Why you need Ultrasound to Correctly Lubricate Bearings

Ultrasound is the best condition monitoring technology for detecting friction, impacting and turbulence. The main purpose of lubrication is to reduce undesired friction and metal-on-metal contact. Ultrasound can detect increased levels of friction as a result of too much, or too little grease.

How to Determine when a Bearing Requires Grease

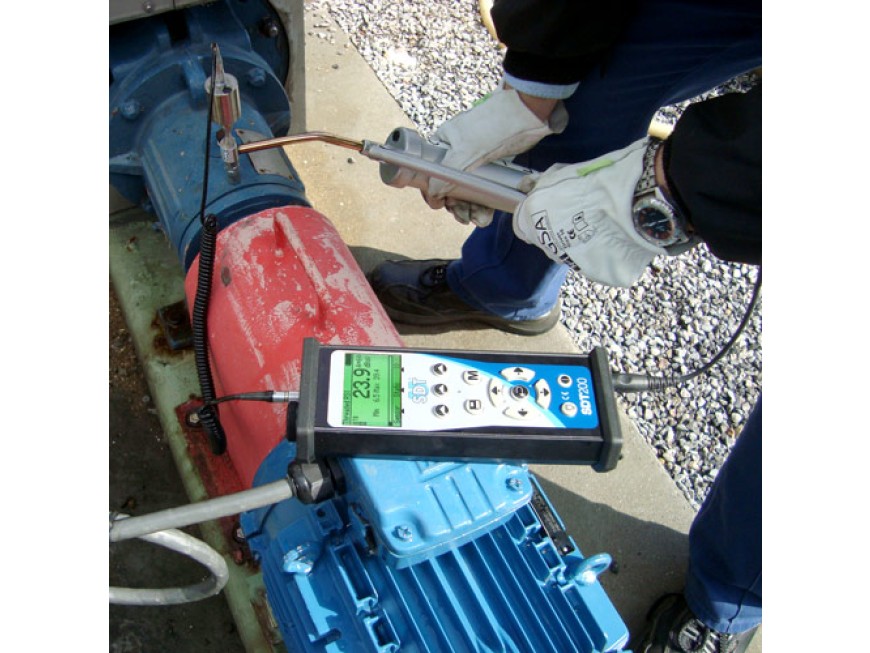

Taking measurements with your ultrasound device is the best, and easiest way to determine when your bearings require grease. Observing changes in dB’s is the first telltale sign that your bearing requires some maintenance So, the first step is to establish a baseline.

How to Grease Bearings Right, Never Under or Over Lubricate again

The only way to know when a bearing is in need of lubrication is monitoring its condition with an ultrasound device. Over time, bearing grease degrades and friction levels increase which is detectable with ultrasound. For this reason, and in order to prolong its life and prevent failure, the bearing needs grease replenishment.

An Ultrasound Device allows users to carefully monitor a bearing during a lubrication task. Both audio and visual representations of the bearings decibel level are displayed to provide greasing guidance. As grease is added to the bearing the decibel levels will decrease. Once dB levels begin to climb slightly, you know you have reached the optimal level of grease.

Ultrasound inspection for bearing lubrication is a technique used to assess the condition and effectiveness of lubrication in bearings. It involves the use of specialized ultrasound equipment to detect and analyze ultrasound signals generated by bearings. Here is a breakdown of how ultrasound inspection for bearing lubrication works:

Equipment Setup:

Ultrasound Device:

An ultrasound inspection device equipped with a sensitive microphone or sensor specifically designed for bearing inspections is used. The device may have adjustable settings to optimize the detection of ultrasound signals.

Sensor Placement:

The ultrasound sensor is positioned in close proximity to the bearing being inspected to capture the ultrasound signals effectively. The sensor may be attached using a magnetic mount or held manually by the inspector.

Bearing Operation:

Bearing Activation:

The bearing is activated, typically by rotating the shaft or applying a load, to initiate the movement and generate the characteristic sounds associated with bearing lubrication.

Ultrasound Signal Capture:

Sensor Placement:

The ultrasound sensor is placed near the bearing housing, typically at specific points of interest such as the bearing outer ring, inner ring, or grease nipple.

Signal Recording:

The ultrasound inspection device records the ultrasound signals emitted by the bearing during its operation. These signals are generated by various factors, including friction, lubrication conditions, and potential abnormalities or defects.

Data Analysis:

Sound Wave Interpretation: The recorded ultrasound signals are analyzed using specialized software or tools capable of processing and interpreting the data. The software helps distinguish between normal operational sounds and abnormal or problematic sounds related to bearing lubrication.

Lubrication Assessment:

The analysis focuses on specific sound patterns and frequencies associated with bearing lubrication. It identifies changes in the ultrasound signals that indicate potential lubrication issues such as insufficient lubrication, over-lubrication, contamination, or degradation of the lubricating oil or grease.

Lubrication Evaluation:

Lubrication Condition: Based on the analysis results, the condition of the bearing lubrication is evaluated. This includes assessing the lubrication effectiveness, identifying any anomalies or deviations from the expected ultrasound patterns, and determining the need for maintenance or lubrication adjustment.

Recommendations:

The inspection report may include recommendations for lubrication replenishment, lubrication intervals, lubrication type or grade, or further diagnostic steps based on the findings.

Ultrasound inspection for bearing lubrication provides valuable insights into the condition and effectiveness of bearing lubrication. By capturing and analyzing ultrasound signals emitted by bearings, this inspection technique helps identify lubrication issues, optimize maintenance practices, and enhance the performance and lifespan of bearings.