CUSTOMIZED TRAININGS-ELECTRICAL, MECHANICAL, ACOUSTIC IMAGING, FURNACE AND OPTICAL GAS IMAGING TRAININGS

Introduction to Thermography

This is a full 2-days course for beginners and anyone interested in infrared thermography and its applications. The course covers the basics of infrared theory and includes demonstrations, camera hands-on training and practical exercises using relevant laboratory sessions.

Course content: Basics of thermography, basics of emissivity and reflected apparent temperature, introduction to electrical and building inspections, infrared camera handling, data analysis and reports, laboratory sessions.

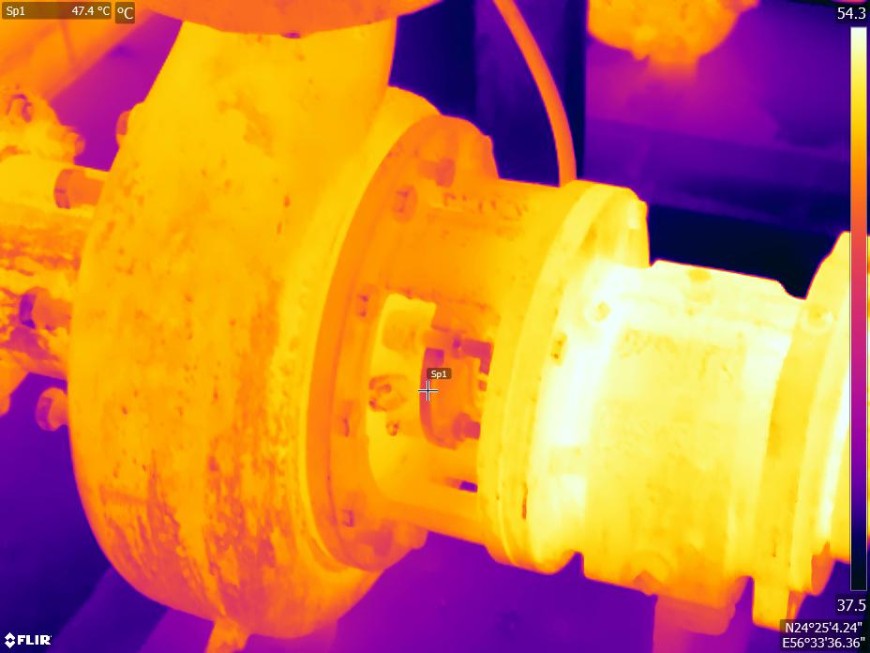

Introduction to Electrical and Industrial Thermography

This course provides a general introduction to infrared thermography and an overview of its specific use for inspections of electrical and industrial systems. It aims at giving you suggestions on what you can do with your infrared camera. During the first day, you learn the basics of thermography and how to use your camera the best way (the first day is identical to the course Introduction to Thermography). The second day you will start with a brief reminder about thermal transfers before you learn about electrical and industrial systems and components, material properties and typical problems and faults.

Course content: Basics of thermography, basics of emissivity and reflected apparent temperature, introduction to electrical and building inspections, infrared camera handling, basics of heat transfer, electrical and industrial systems, important properties of materials, common problems, case studies, common mistakes, application guidelines, data analysis and reports, laboratory sessions.

Furnace Thermography Training

Optical Gas Imaging Thermography Certification Courses

Skilled users of the FLIR GF-Series and legacy GasFindIR cameras can inspect more than 3,000 connections per day in many applications—six times more than inspectors using current sniffer technology. This provides organizations the most efficient LDAR inspection technology so they can meet many required emission reduction actions, including regulatory oversight like the US EPA OOOOa for the Oil and Gas Industry.

Students in the Optical Gas Imaging Certification course will learn how to set up and operate FLIR optical gas imaging (OGI) cameras to ensure maximum proficiency. They will learn how to optimally adjust their cameras for varying field conditions to find gas leaks and under what environmental parameters gas leaks are most easily found, somewhat easy to find, and difficult to find. With this, students be able to ensure their OGI camera and inspections meet a wide variety of operating envelope challenges, with the ultimate goal of meeting any required work practices or verification checks of the technology.

Customized trainings in electrical, mechanical, furnace, and optical gas imaging provide tailored education and skills development for professionals in specific areas of interest. Here are some benefits of customized trainings in these fields:

Targeted Knowledge Acquisition:

Customized trainings focus specifically on the areas of electrical, mechanical, furnace, or optical gas imaging that are relevant to the participants’ needs. The training content is tailored to address the specific challenges, techniques, and equipment used in these disciplines, ensuring that participants acquire knowledge that is directly applicable to their work.

Practical Application:

Customized trainings emphasize hands-on practical exercises and real-world scenarios. Participants get the opportunity to apply the learned concepts and techniques in simulated or actual work environments. This practical approach enhances understanding and builds confidence in applying the knowledge gained during the training.

Equipment Familiarization:

Customized trainings provide participants with the opportunity to become familiar with the specific electrical, mechanical, furnace, or optical gas imaging equipment they will be using in their roles. This includes understanding the features, functions, and operation of the equipment, as well as best practices for its safe and effective use.

Industry-Specific Standards and Regulations:

Customized trainings ensure participants are knowledgeable about the industry-specific standards, regulations, and guidelines relevant to their field. This includes compliance with electrical codes, safety regulations, mechanical standards, furnace operation guidelines, or optical gas imaging protocols. Understanding and adhering to these standards is crucial for maintaining safety, quality, and regulatory compliance.

Problem-Solving and Troubleshooting Skills:

Customized trainings focus on developing problem-solving and troubleshooting skills specific to electrical, mechanical, furnace, or optical gas imaging. Participants learn how to analyze complex situations, diagnose issues, and devise effective solutions. This enhances their ability to address challenges and minimize downtime in their respective fields.

Safety and Risk Mitigation:

Customized trainings prioritize safety considerations and risk mitigation strategies in electrical, mechanical, furnace, or optical gas imaging applications. Participants learn about potential hazards, safety protocols, and best practices for minimizing risks associated with these disciplines. This helps create a safety-conscious work environment and reduces the likelihood of accidents or incidents.

Customized Case Studies and Examples:

Customized trainings incorporate relevant case studies and examples specific to electrical, mechanical, furnace, or optical gas imaging. These real-life scenarios provide participants with practical insights into the challenges, solutions, and best practices relevant to their field. Customized case studies help participants relate the training content to their day-to-day work and improve their decision-making abilities.

Continuous Professional Development:

Customized trainings support continuous professional development by keeping participants updated on the latest advancements, techniques, and technologies in their respective fields. This ensures that professionals stay current with industry trends and maintain a competitive edge in their careers.

Networking and Collaboration:

Customized trainings often bring together professionals from the same industry or organization, creating opportunities for networking and collaboration. Participants can exchange knowledge, share experiences, and build professional relationships with peers who face similar challenges. This networking aspect of customized trainings can foster collaboration and learning beyond the training sessions.

Enhanced Performance and Efficiency:

Customized trainings enable professionals to improve their performance and efficiency in their specific domains. By acquiring specialized knowledge and skills, participants can optimize their processes, reduce errors, increase productivity, and contribute to the overall success of their organizations.

Customized trainings in electrical, mechanical, furnace, and optical gas imaging offer a range of benefits, including targeted knowledge acquisition, practical application, equipment familiarization, adherence to industry standards, problem-solving skills, safety considerations, customized case studies, continuous professional development, networking opportunities, and enhanced performance and efficiency.