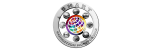

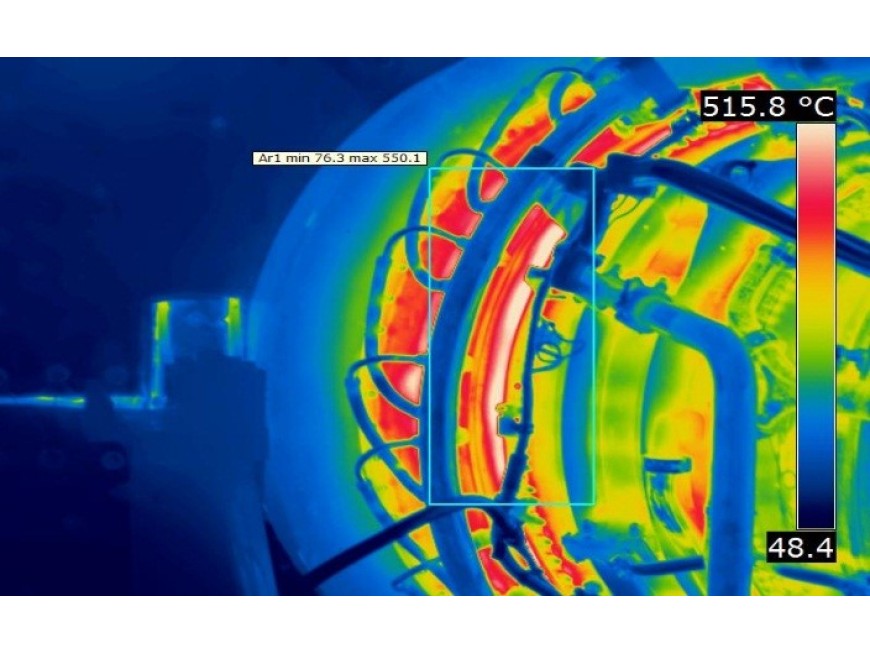

Thermal imaging is the only technology that allows operators to inspect all electrical and mechanical components of the turbine and the surrounding electrical system. Both for electrical and mechanical components, the general rule is that a component will become hot before it fails. Thermal imaging cameras spot this rise in temperature before a failure occurs. These hot spots will show up clearly in the thermal image.

A thermal camera can show gearbox and motor issues including shaft misalignments, as well as elusive electrical issues such as loose connections and imbalanced loads. The versatility of thermal cameras enables maintenance operators to make the most out of their preventive maintenance program.

Thermal Imaging camera also helps in detecting hotspots and insulation defects on the surface of steam and gas turbines thereby improving efficiency and performance of turbines.

Gas and steam turbine thermal inspections involve the use of thermal imaging technology to assess the performance, efficiency, and condition of gas and steam turbines. These inspections play a crucial role in detecting potential issues, optimizing turbine operation, and ensuring the reliability of power generation systems. Here are key points related to gas and steam turbine thermal inspections:

Purpose of Inspections:

Gas and steam turbine thermal inspections aim to identify anomalies, inefficiencies, or potential failures in turbine components. The inspections help detect issues such as overheating, insulation degradation, coolant leaks, air ingress, improper cooling, or faulty seals. By identifying these issues, inspections contribute to improving turbine performance, efficiency, and reliability.

Thermal Imaging Technology:

Thermal imaging cameras are used to capture infrared radiation emitted by the surfaces of gas and steam turbines. These cameras detect temperature variations and generate visual images known as thermograms. Thermograms display different colors or temperature gradients, representing variations in temperature. By analyzing the thermograms, inspectors can identify areas of concern and evaluate the condition of the turbines.

Components Inspected:

Gas and steam turbine thermal inspections cover various critical components, including turbine blades, rotor discs, bearings, seals, casings, combustion chambers, and exhaust systems. The inspections focus on areas where temperature differentials or abnormal thermal patterns may indicate issues or inefficiencies.

Overheating Detection:

One of the primary objectives of gas and steam turbine thermal inspections is to detect overheating. Overheating can indicate problems such as rubbing, excessive friction, coolant flow issues, inadequate cooling, or component wear. Thermal imaging helps identify temperature anomalies that may not be visible to the naked eye, allowing for early intervention and maintenance.

Efficiency Optimization:

Thermal inspections contribute to optimizing the efficiency of gas and steam turbines. By detecting heat losses, thermal imbalances, or cooling inefficiencies, inspections provide insights into areas that require adjustments or maintenance. Addressing these issues can improve turbine efficiency, reduce fuel consumption, and enhance power generation performance.

Condition Monitoring:

Gas and steam turbine thermal inspections support condition monitoring efforts. By conducting regular inspections and comparing thermograms over time, inspectors can track changes and trends in temperature patterns, identifying gradual degradation or developing faults. This information aids in predictive maintenance planning and can help prevent unexpected failures.

Non-Destructive Testing:

Gas and steam turbine thermal inspections are non-destructive, meaning they do not require disassembly or physical contact with the turbines. This allows inspections to be performed while the turbines are in operation, minimizing downtime. Non-destructive testing is particularly advantageous for critical and high-demand power generation systems.

Reporting and Documentation:

Following a gas and steam turbine thermal inspection, a detailed report is typically prepared, documenting the findings, including identified issues, recommendations, and actions taken. This report serves as a reference for future inspections, aids in maintenance planning, and supports compliance documentation.

Professional Inspection Services:

Gas and steam turbine thermal inspections are often conducted by qualified thermographers or certified inspectors with expertise in power generation systems and thermography. These professionals possess the knowledge and experience to accurately interpret thermal images, identify anomalies, and provide recommendations for maintenance or repairs.

Gas and steam turbine thermal inspections are essential for ensuring the efficient and reliable operation of power generation systems. By detecting overheating, identifying potential issues, and supporting maintenance strategies, these inspections contribute to optimized performance, reduced downtime, and increased turbine lifespan.