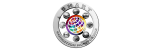

Tank Farms Aerial Inspection

Tank inspections by drone help you to detect corrosion and other issues inside your storage tanks. Whether you are in the oil and gas industry or need to check storage tanks in a maritime setting, our drones offer the perfect solution. Tank inspections can be a challenge not least because of the safety risks they can pose to inspectors.

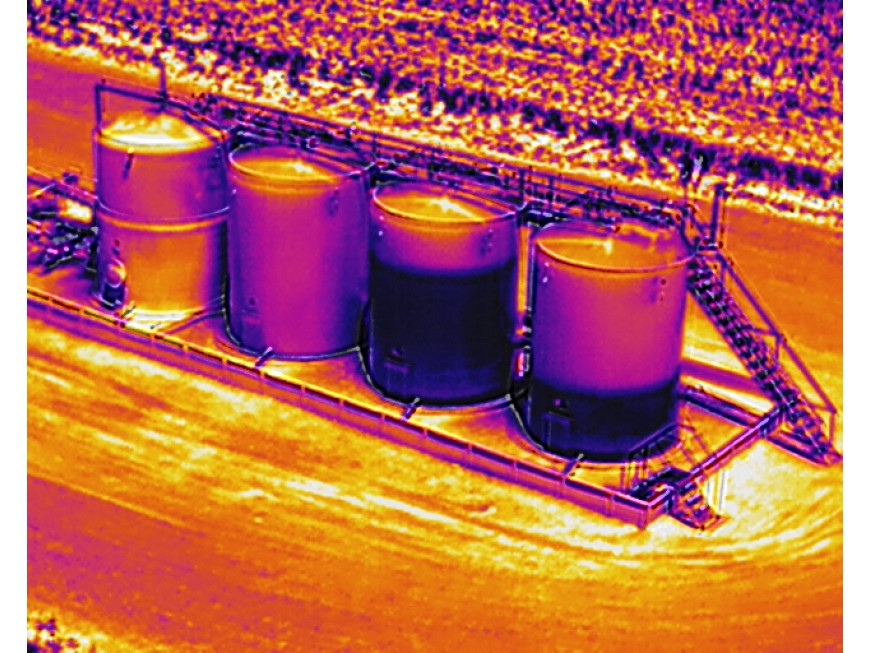

On the other hand, can help to eliminate this risk by protecting your inspectors and carrying out inspections safely while being operated outside of the tank. We offer years of expertise in thermal imaging, OGI and UAV services and we would be happy to tell you more about our services and how much easier we make tank inspections for our clients. Also it is possible to detect hydrocarbon gas leaks using our drone solutions when the drones are integrated with our FLIR GIS320 solution.

Oil and gas tank thermal inspections involve the use of thermal imaging technology to assess the condition, integrity, and performance of storage tanks used in the oil and gas industry. Here are some key points related to oil and gas tank thermal inspections:

Purpose of Thermal Inspections:

Thermal inspections of oil and gas tanks are conducted to identify potential issues or anomalies that may affect the structural integrity, insulation, or safety of the tanks. The inspections help detect problems such as leaks, corrosion, insulation degradation, uneven temperature distribution, or faulty equipment.

Thermal Imaging Technology:

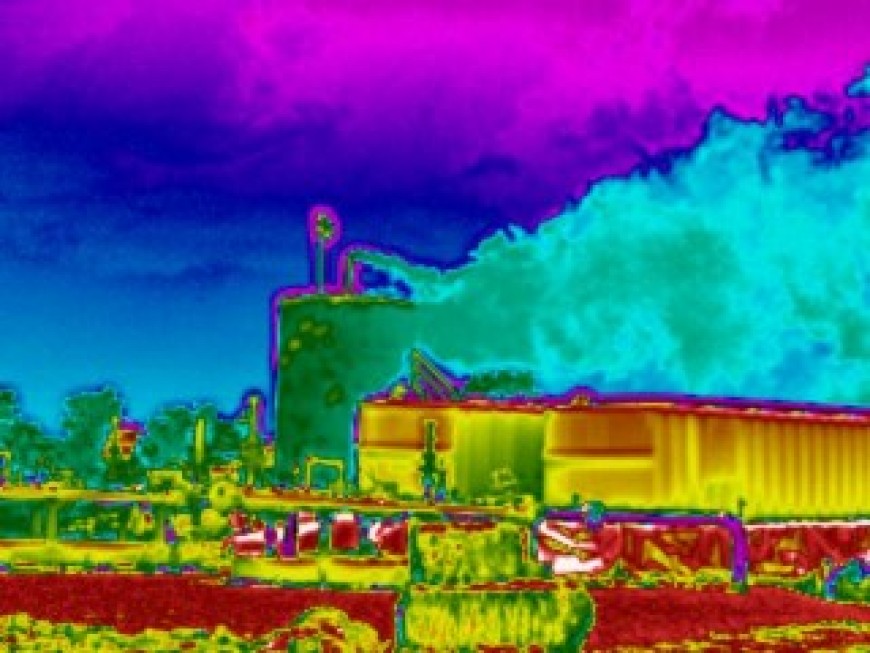

Thermal imaging cameras are used to capture infrared radiation emitted by the surfaces of the tanks. These cameras detect temperature variations and generate visual images known as thermograms, where different colors represent different temperature ranges. By analyzing the thermograms, inspectors can identify areas of concern and evaluate the condition of the tanks.

Leak Detection:

One of the primary objectives of oil and gas tank thermal inspections is to detect leaks. Thermal imaging can identify temperature differences caused by leaking fluids or gases. Leaks appear as hot spots or cold spots on the thermograms, depending on the nature of the stored material and the surrounding environment.

Corrosion Assessment:

Thermal inspections can help identify areas of corrosion on the tank’s surface. Corrosion often causes temperature variations due to differences in heat conductivity between the corroded and non-corroded areas. By detecting these temperature anomalies, inspectors can pinpoint areas that may require further inspection or maintenance to prevent structural degradation.

Insulation Evaluation:

Thermal inspections assess the effectiveness of the tank’s insulation. Inadequate or damaged insulation can result in heat loss or gain, leading to reduced efficiency and increased energy consumption. By examining temperature patterns on the tank’s surface, inspectors can identify areas with compromised insulation and recommend repairs or enhancements.

Equipment Performance:

Thermal inspections can also evaluate the performance of equipment within the tank, such as heating or cooling systems. By monitoring temperature distribution and identifying any irregularities or malfunctions, inspectors can identify issues that may affect the proper operation of the equipment.

Safety Considerations:

Oil and gas tank thermal inspections contribute to safety by identifying potential hazards or risks associated with the tanks. For example, thermal inspections can detect hotspots that may indicate electrical faults, overheating equipment, or fire risks. Identifying such issues allows for timely intervention and preventive measures to ensure the safety of personnel and assets.

Compliance with Regulations:

Thermal inspections of oil and gas tanks help ensure compliance with industry regulations and standards. Regular inspections are often required by regulatory bodies to verify the integrity and safety of storage tanks. By adhering to inspection guidelines and standards, companies demonstrate their commitment to maintaining safe and reliable operations.

Reporting and Documentation:

Following a thermal inspection, a detailed report is typically prepared, documenting the findings, including any identified issues, recommendations, and actions taken. This report serves as a record of the inspection, facilitates compliance documentation, and provides a reference for future inspections and maintenance activities.

Professional Inspection Services:

Oil and gas tank thermal inspections are typically conducted by trained professionals who specialize in thermal imaging and have experience in the oil and gas industry. These professionals possess the knowledge and expertise to accurately interpret thermal images, identify anomalies, and provide recommendations for maintenance or repairs.

Oil and gas tank thermal inspections play a crucial role in maintaining the integrity, safety, and efficiency of storage tanks. By detecting leaks, assessing corrosion, evaluating insulation, monitoring equipment performance, and ensuring compliance with regulations, these inspections contribute to the smooth and reliable operation of oil and gas facilities.