Vibration Analysis Services And Troubleshooting

The most common equipment vibration problems are often solved in industry without the use of specialty engineering. However, some noise and vibration problems require a more in-depth approach—one that involves a combination of computer simulation, specialty field measurements, and/or advanced data analysis techniques. When these more difficult and challenging dynamics problems arise, they call on us for expert consulting and field services.

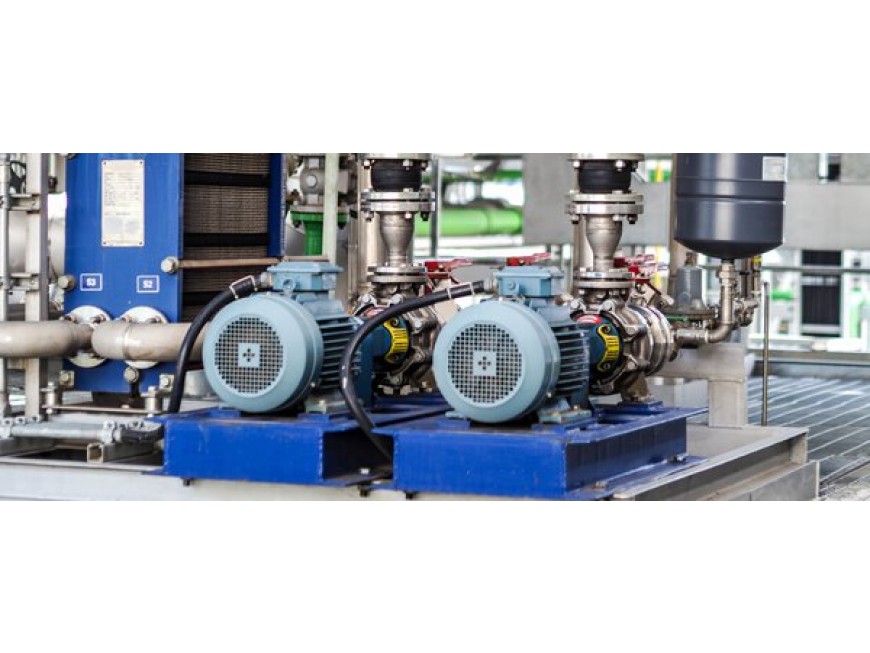

Vibration Analysis (VA), applied in an industrial or maintenance environment aims to reduce maintenance costs and equipment downtime by detecting equipment faults. VA is a key component of a Condition Monitoring (CM) program, and is often referred to as Predictive Maintenance (PdM). Most commonly VA is used to detect faults in rotating equipment (Fans, Motors, Pumps, and Gearboxes etc.) such as Unbalance, Misalignment, rolling element bearing faults and resonance conditions.

VA can use the units of Displacement, Velocity and Acceleration displayed as a Time Waveform (TWF), but most commonly the spectrum is used, derived from a Fast Fourier Transform of the TWF. The vibration spectrum provides important frequency information that can pinpoint the faulty component.

Vibration analysis services encompass a range of techniques and methodologies used to assess the condition and performance of machinery and structures based on their vibration characteristics. Here are some different vibration analysis services commonly offered:

Condition Monitoring:

Vibration analysis is utilized as part of condition monitoring programs to continuously monitor the vibration levels of machinery and equipment. By regularly analyzing vibration data, changes in vibration patterns can be detected, allowing for early identification of potential faults or abnormalities.

Machinery Diagnostics:

Vibration analysis is applied to diagnose machinery problems and identify the root causes of vibrations. By analyzing vibration signals from various machine components, such as bearings, gears, shafts, and rotors, experts can determine if there are issues like misalignment, imbalance, mechanical looseness, wear, or other faults.

Structural Health Monitoring:

Vibration analysis is used to monitor the health and integrity of structures, such as buildings, bridges, dams, and pipelines. By measuring and analyzing vibration responses, engineers can assess the structural dynamics, detect any changes or anomalies, and evaluate the structural condition and performance.

Balancing Services:

Vibration analysis is employed to perform dynamic balancing of rotating machinery, such as motors, fans, pumps, and turbines. By analyzing the vibration signals during operation, experts can determine the unbalance conditions and provide recommendations for corrective measures to improve balance and reduce vibration levels.

Resonance Analysis:

Vibration analysis is used to identify and mitigate resonance issues in machinery and structures. Resonance occurs when the natural frequency of a system matches the excitation frequency, resulting in excessive vibrations. Vibration analysis helps identify resonant frequencies, assess their impact, and implement mitigation strategies to prevent resonance-related failures.

Fault Detection and Failure Analysis:

Vibration analysis is employed to detect and diagnose faults in machinery and equipment. By analyzing vibration signatures, experts can detect specific fault conditions, such as bearing defects, gear tooth damage, shaft misalignment, and electrical faults. Vibration analysis can also be used in failure analysis investigations to determine the root causes of equipment failures.

Predictive Maintenance:

Vibration analysis is a key component of predictive maintenance programs. By monitoring and analyzing vibration data, maintenance teams can predict potential machinery failures, schedule maintenance activities accordingly, and avoid unexpected breakdowns and downtime.

Training and Consultation:

Vibration analysis services often include training and consultation to educate personnel on vibration analysis techniques, data interpretation, and best practices. Experts provide guidance on implementing effective vibration analysis programs and offer insights into optimizing machinery performance and reliability.

These are just a few examples of the different vibration analysis services available. Vibration analysis plays a crucial role in assessing the health and performance of machinery and structures, enabling proactive maintenance, minimizing downtime, and optimizing operational efficiency.