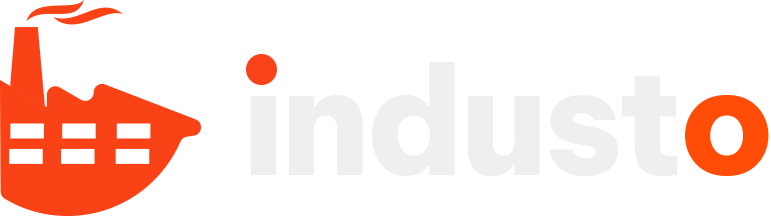

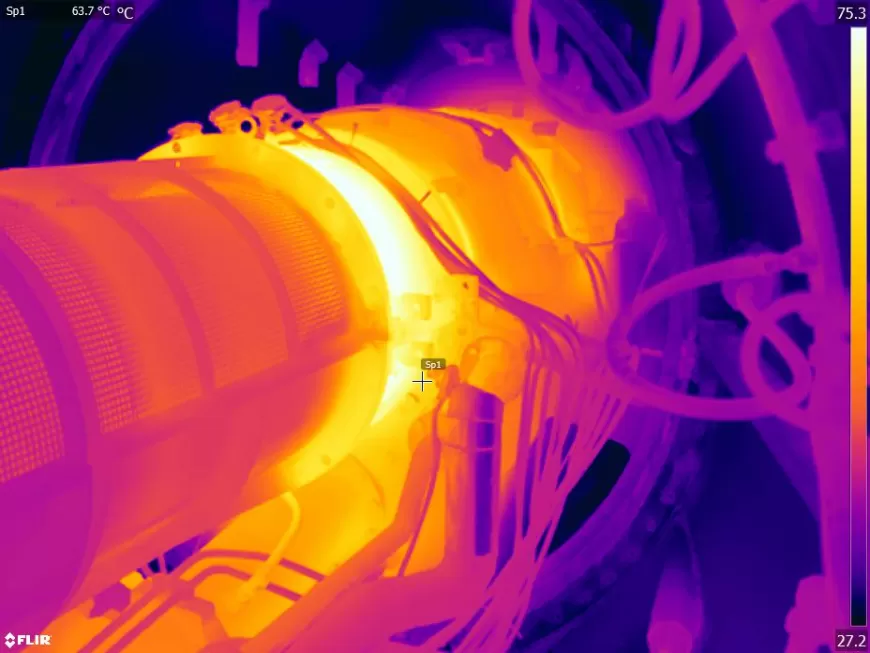

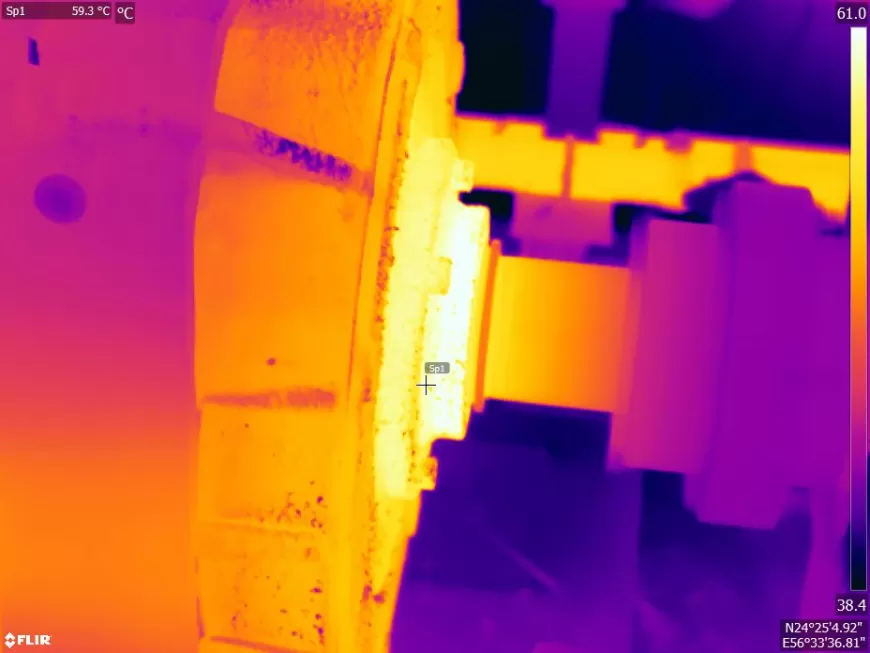

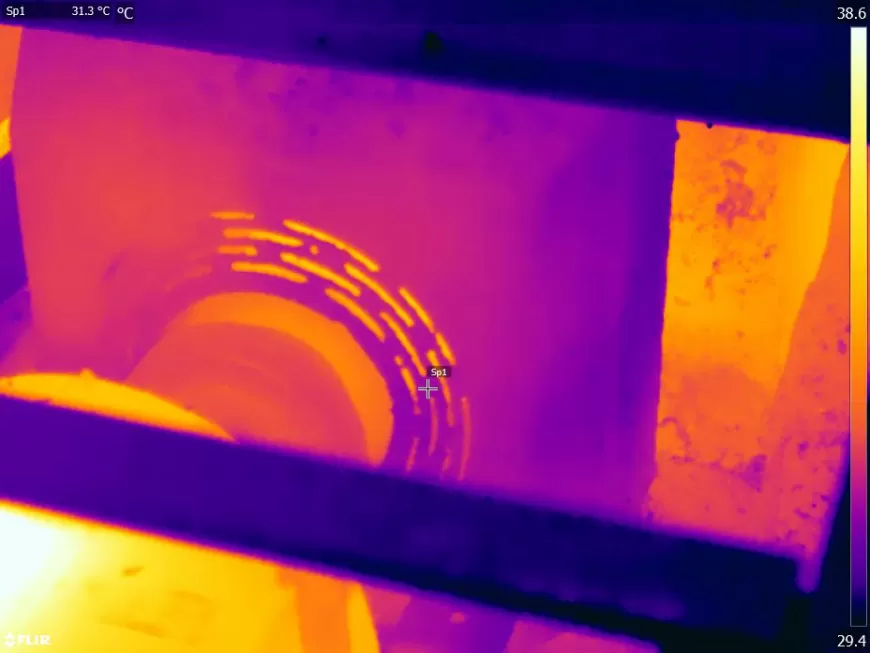

Thermal Imaging technology plays a vital role in inspection of mechanical rotary equipments along with vibration analysis and Airborne Ultrasound for Condition Monitoring. Along with troubleshooting, thermal imagers can also help optimize the production process itself as well as monitor quality control. Pumps, Motors, Turbines, Bearings, Conveyor belts, Process Valves and other mechanical machinery can be inspected and diagnosed with the help of thermal imaging. As a non-contact measurement tool that also makes invisible heat issues visible, thermal cameras let technicians inspect production equipment more safely even at peak operation.

Mechanical thermography inspections involve the use of thermal imaging technology to assess the performance, condition, and integrity of mechanical systems and equipment. Here are key points related to mechanical thermography inspections:

Purpose of Inspections

Thermal Imaging Technology

Equipment and Systems Inspected

Overheating Detection

Preventive Maintenance

Energy Efficiency

Condition Monitoring

Non-Destructive Testing

Reporting and Documentation

Professional Inspection Services

Mechanical thermography inspections play a crucial role in ensuring the reliable performance, safety, and energy efficiency of mechanical systems and equipment. By detecting overheating, identifying potential issues, and supporting preventive maintenance, these inspections contribute to optimized operations, reduced downtime, and increased equipment lifespan.