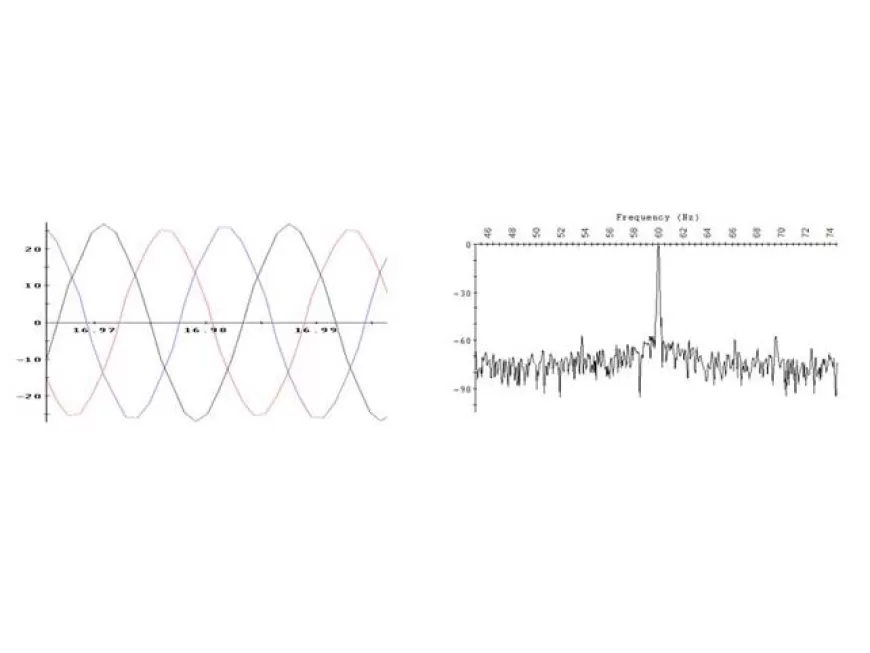

Motor Current Signature Analysis

Motor Current Signature Analysis (MCSA) is a technique used to determine the operating condition of induction motors without interrupting production. Motor current signature analysis is that it is sensing an electrical signal that contains current components. MCSA detect the faults at an early stage and avoid the damage and complete failure of the motor. Proper analysis of MCSA results assists in identifying:

- Rotor bar damage

- Misalignment/ unbalance

- Foundation looseness

- Static eccentricity

- Dynamic eccentricity

- Stator mechanical /electrical faults

- Defective bearings

- Coupling health, including direct, belted and geared systems

- Load issues

Motor Current Signature Analysis (MCSA) is a technique used to assess the health and condition of electric motors by analyzing their electrical current signatures. By monitoring and analyzing the motor current waveform, MCSA provides valuable insights into the motor’s operational status and identifies potential faults or abnormalities. Here are some benefits of Motor Current Signature Analysis:

Early Fault Detection

Condition Monitoring

Non-Intrusive Testing

Cost Savings

Improved Energy Efficiency

Fault Diagnosis and Root Cause Analysis

Increased Safety

Data-Driven Decision Making

Motor Current Signature Analysis offers numerous benefits in terms of early fault detection, condition monitoring, cost savings, improved energy efficiency, fault diagnosis, safety enhancement, and data-driven decision making. By utilizing MCSA as part of a comprehensive motor maintenance program, organizations can optimize motor performance, reduce downtime, and enhance operational reliability.